Author: Rick

Big News!!!

Antiqueiron.media will soon be doing video feeds!

This weekend was very productive. James Hunt, has finally brought my technology into the 21st century.

Stay tuned and look for the links that will be created to YouTube.

As always thanks to everyone that supports the media/ mafia. I encourage everyone to subscribe and follow all the different formats created for the tractor enthusiast.

I will also be creating a patreon account for those willing to help support my growing endeavors in bringing antique agricultural media for the public’s enjoyment

There is one more step in the process. I’m seeking a graphic design artist to help create a logo. This will demonstrate the professional presence moving forward.

The “Chase”

Its amazes me to think of all the different antique tractors I have owned over the past few years. I’ve been collecting lawn tractors far longer, but I really didn’t own farm tractors until 2015. Since that July, I discovered the challenge to purchase is just as enjoyable.

My attitude toward my tractors make them only toys to me. I don’t “need to” own anything. I make suitable purchases based on what fits into my expendable budget after my responsibilities are met. My collection may not be nearly impressive as some of my friends. In risk of sounding selfish, the only one that I feel really needs gratification of what I own is me!

Don’t misunderstand, I like to share my collection in a manner for others to enjoy. I would much rather have others experience the wonder of a peice for it’s glory and beauty. It has nothing to do with a fact that I own it.

That’s one of the reasons I pursue writing and a majority of what I share is in the antique tractor genre. I’m very fortunate to make friends with many wonderful people also caught in the passion. I also take great joy in influencing others to embrace the interest. Writing is just another form of pursuing the chase. There will never be a shortage of material to write about.

I like to report more than the mechanics of tractor. The challenge is to discover history of a particular peice. Sometimes, the story as to why a owner has it is more interesting than the tractor itself. My personal collection has one or two that have a special story.

I like to make a deal. I quickly learned there is more satisfaction in the transaction when both parties walk away happy. I approach every sale with straight forward honesty, whether I’m the buyer or the seller. I’d like to think that’s why I usually come away with a new friend in the bargain.

The last three antique farm tractors, I have purchased came from the same seller. Jim Edwards is a fair, just gentleman and great fun to work with. That, and becoming a respected friend, gives me the confidence to be a repeat customer. Jim is actually now my tractor dealer. I actually seek out his opinion on tractor matters. I consider myself fortunate to have Jim’s guidance. The Edwards may cull out a red tractor from their herd now and then. Chances are good it just moves into my collection.

The Edwards family taught me to also consider making purchases which have potential to appreciate in value. Because of this, I must confess that tractors maybe aren’t just toys. A collection is a major investment. Tractor purchases have become part of my financial planning. I see them similar to buying on the stock market. Buying with only a sentimental reason isn’t always a good plan. Altering my way of thinking has caused my collection monetary value to grow.

Brand values differ depending on locations. In explaining my observation, my region is very “pro John Deere, IH and Oliver” Where as if in another region it may be Case, or Allis Chalmers oriented. Personal preference is also a factor. I undoubtedly admit to being a red guy, but I have owned, or even still do own, “off brands”

I take full consideration into all aspects of the prospective buy. There are certain brands that I enjoy, but I might steer clear of ownership. My conservative tendency is to buy something I can easily resell if I need to. I don’t recommend my attitude for everyone though. That’s just my outlook on my collection.

I have my horror stories on deals that have failed. I had actually walked away from a purchase of a rare lawn tractor. I discovered the seller was attempting unjustified sales techniques. It was sad that the deal had gone bad, I would have been a repeat customer with him. The rare lawn tractor would have been a great addition, but the deal wasn’t worth working with a unscrupulous character.

Early 2017, I ended up making a purchase I wasnt really intending too. I had discovered the tractor through social media. The man had done a wonderful restoration of a hard to find model and was attempting to sell it. I reached out to the man, only to compliment his workmanship. We text, later to have a phone conversation, and had a very friendly visit. He finally asked if I wanted to buy… I made an offer.

Reference “And that’s the Case” a earlier article found in this blog. There is a more detailed explanation of the Michigan adventure.

Because of the adrenaline rush, of buying and selling, I will take on flip tractors. I have managed to turn a small profit, but more importantly I gain opportunity to meet new people.

My collection seems to always change. I always have two or three farm tractors, and more lawn tractors that I loose count at times. The group isnt always the same though. I tend to embrace my family heritage and will have red power, but I have my eye on other brands.

However owning tractors gets labeled. As a hobby, passion, or addiction, this is just something many people enjoy for many different reasons.

Then & Now, Ag Hauling part 3

A typical day for a grain hauler usually begins very early in the morning. The grain company I work for most always has the trucks loaded for the following work day. This is to take full advantage of the receiver’s hours of operations. A grain hauler generally works a 12 to 14 hour day on average. I can remember when the work day was longer.

Modern technology has made a difference in wait times. The only down side is human interaction is far less than before. Most operations have a similar computer process being utilized. Information is either entered in a kiosk mounted scale side or communicated through a speaker or phone style headset. CB radios are even used in some cases.

Every system is similar. Some companies distribute a plastic tag that is hung in the windshield so a scanner can read and identify the truck. Other companies use a small plastic card about the size of a credit card. The card is swiped at a kiosk at some point during in processing and out processing. Sometimes the card can be read at several stations as the truck moves through the facility.

During in process, the truck gets weighed. This is generally when the computer tag is identified. The load will get probed and graded at some point before unloading. Contact is made with the scale operator and any other additional load information is taken.

Out process is another scale. The tag is again read and a grain recieved ticket is printed. You may not have much contact with a company representative, but rest assured you have been carefully monitored via camera.

The computer systems are very efficient and speed up time spent in the facility. The plastic tags however aren’t all universal to several facilities. In fact the same company will differ. ADM Decatur uses a hanging tag, and the St Louis, MO / Sauget, IL river terminals use cards. Most grain haulers have a large collection of different tags and cards. The trick is to make sure incompatible tags do not interfere with the system currently in use.

Rock quarries even use a computer system. The major difference is there isn’t inbound weight taken every single time being loaded.

End loaders, at quarries, are much more accurate when estimating amounts now. In past times a operator just got good simply by repetitive loading. Modern machinery is now equipped with a scale in the loader bucket.

I can remember before mechanical grain probes were used. Most scales had a walk way for a person to take samples of the incoming truck. The mechanical probe now uses electrical, hydraulic, and vacuum to retrieve the sample. Depending on the facility, there are even cameras monitoring where the probe is being placed

Where I’m employed, has become very modern. There is inbound and outbound scales to help process quickly. The inbound scale has a mechanical probe and the whole elevator is monitored via camera. Communication is maintained with the truck traffic using the CB.

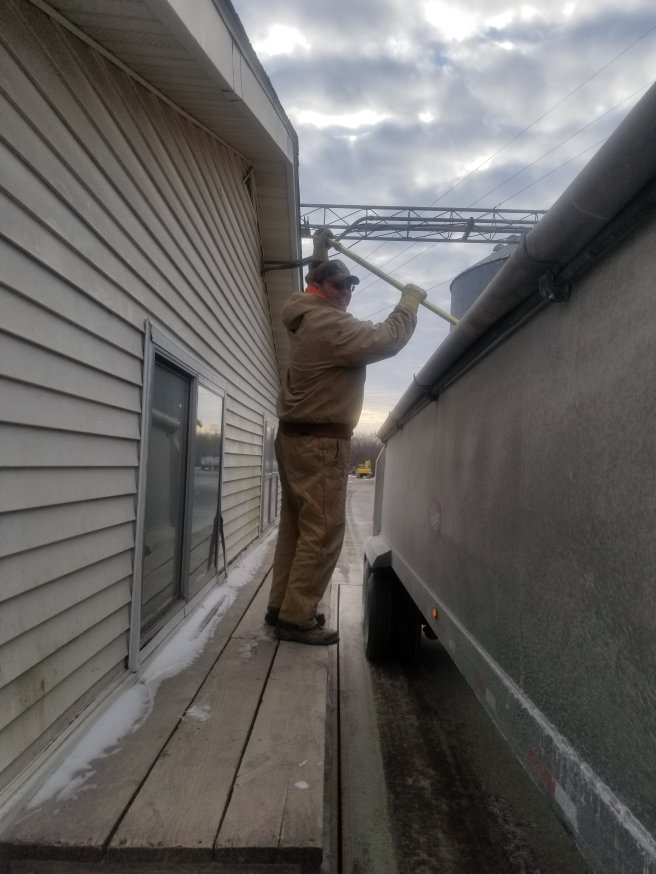

Outbound grain loading has greatly improved at BAB. The elevator employee no longer has to stand on a perch above the truck to load, enduring hazards such as weather, falling, breathing dust, and noise.

There is now a central located building where the load is monitored via camera and controlled by electric doors. This is safer since the loader and driver can communicate using radio rather than shouting to be heard.

There are other grain operations even more state of the art than we are at BAB Grain. I have actually loaded on a scale. This method insures a perfect legal weight placement.

Grain handling has come into the 21st century using modern technology. I don’t consider myself that old, but I vaguely remember before cellphones, and the coming age of computers. Modern life hardly happens without using personal devices, to the point we take it for granted.

This will conclude my series on ag hauling. I hope you enjoyed the small peek into my work day. I know some of my following “know the drill”and relate. For everyone else, this may have been behind the scenes learning.

I want to thank my employer, Greg Boesdorfer, and fellow coworkers for making this article possible. A majority of the trucks pictured, in the article, are the BAB fleet. It was easier, sharing a behind the scene view, using some pictures of the BAB Grain facility.

Special thanks to Mark Enslow for helping stage some of the pictures. Mark has been with BAB for thirty plus years and witnessed many of the facility changes that have made grain handling, safer and more efficient.

Then & Now Ag Hauling, part 2

Most of the advancement, I have witnessed, in Ag support have been better equipment utilized. Electronic tools have started to making a driver’s work more efficient.

Tarping has major improvement in my time. I didn’t start to work with tarps until I started driving semi trucks. My first encounter was major work and unsafe by today’s standard.

I literally had to manipulate the tarp on a loaded dump trailer very much like a flat bed operator still covers freight. There were no supporting metal “bows” the load was covered by a large one peice canvas that was fitted to the trailer. Rubber straps held it in place and the only fixed point was on the center front of trailer. This method, of cover, is dirty and labor intensive. Climbing and throwing the tarp had its fall risks. The major trick was folding and rolling up the tarp properly to fit in a basket designed to hold it when not in use. I’m glad I was young and more agile when I worked this method.

The next type of tarp method I learned was much safer since the driver stayed on the ground….in ideal circumstances anyway. The tarp was fastened down the right side of the trailer. Generally there would be four two inch straps that buckled down the left side to hold it secure. Some tarps had a front and rear cap that was secured with rubber straps. These caps had to be flipped over onto the main body before the tarp could be rolled over to the right side. To roll the tarp, a handle is carried that could be inserted into the end of the rolling pipe. Most have a rope fastened to the roll pipe midway to bring the tarp back over and secure it again

Using permanent mounted front and rear caps make a strap tarp safer like the one pictured. The driver can keep his feet on terre firma.

Sounds pretty simple and efficient? Well it may look good on paper, but let’s talk about real life. This method has pros and cons. There is a little more give way when hauling bulky product. Think of it like an over packed suitcase. This tarp style is more forgiving.

A driver learns to sling the return rope back and forth across the trailer with practice. Leaving the rope draped across during the loading tended to bury the rope. That makes for a difficult chance to cover the load. I learned to stow the tarp handle securely, that tool is very necessary to uncovering a load.

Sure lock tarps are generally the most widely used now in the industry. This method is fastened down the right side. The secured tarp is rolled and tucked under a ridge down the left side. The handle is the locking device to hold the tarp tightly. This method is quick and effective.

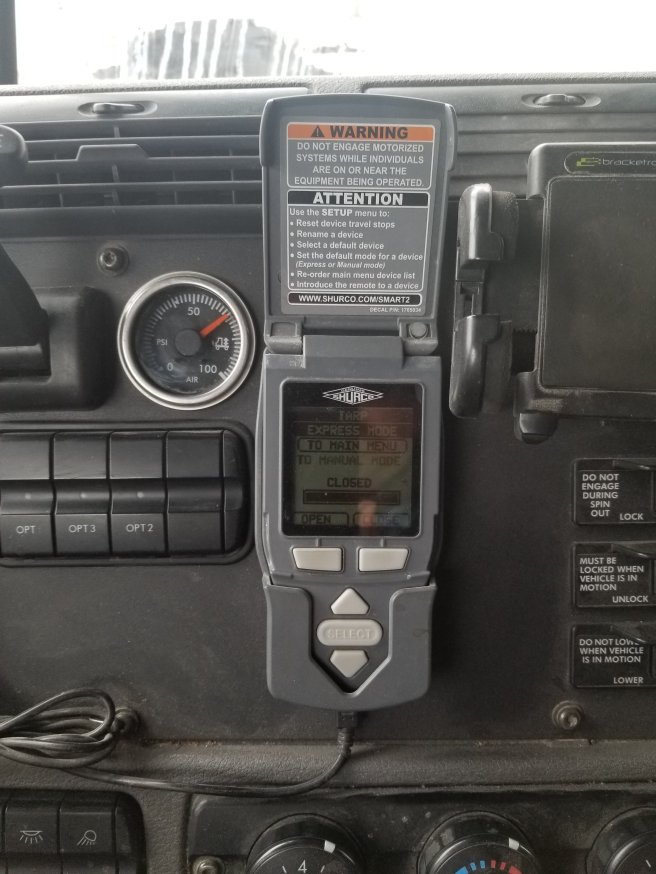

Sure lock tarps recieved a great improvement in recent years. Manually manipulating is becoming obsolete now. Electric motors now do the labor and a driver can control opening and closing the tarp with a remote control.

This convenient option saves time, and effort. Hopper trailer gates can also be controlled via a remote as well.

The control is similar to a all in one remote we enjoy controlling our home entertainment.

The cellular phone made a major difference in ag support. Now a day drivers can stay in touch with dispatch far easier. I really dont remember life before the technology. Before I had a phone I could be contacted with a pager when I hauled feed. Cell phones are more than modes of communication though. Smartphones are great to defeat boredom when committed to a wait in line.

Part 3 will be my final sharing of this article. I will be explaining the technical advancement of most terminals, quarries, and even some local elevators.

Then & Now, Ag Hauling. part 1

In early May, 1980 I “legally” became a commercial driver. I had actually been mastering the skills to operate a truck far sooner, when my leg was strong enough to push the clutch and I could see over the steering wheel. Hank Williams Jr may have been born to boogie. I was born to drive!

I have been a hired driver from the very minute I held a valid driver’s license. The truck I took my road test in was loaded with hay for me to deliver just as soon as the state certified me capable. Granted there may be a little looking the other way before then. Not a lot of questions were asked to country kids when they were being productive members of the work force.

Illinois alphabetically ranked skill training different when I first acquired my license. Class A now was a Class D then. When the federal government mandated the CDL program things changed. I didn’t qualify to drive semi when I was sixteen, I held a Class C. Youth drivers have always had a little difficulty obtaining a combination vehicle license, let alone using it. It may have been a little easier then.

I had military training to drive truck. In 1983, after my release from training duty, I visited the DMV. The State of Illinois granted me a civilian equivalent to my military license by my simple display of credentials. In all the years after that, I have yet to actually prove my abilities with a road test.

I finally started my semi truck driving career in 1988. Minus a short time, here and there, I have driven a truck for the past 31 years. My experience is vast working for many different companies and hauling a multitude of diverse product. I have experience with many specialty trailers. Agriculture holds my heart though, and a little under half of my driving career has been supporting that. A hopper bottom, end dump, and tanker are the most useful tools of the trade for Ag support. These are what I like to see following me in my mirrors.

I have to admit to seeing change in the industry. For what’s changed there is also sameness. There has been some improvement and labor saving introduced, but the basic work really hasn’t changed. Lines will probably always exist as long as grain needs to be transported. A military terminology sums it up perfectly. “Hurry up! and wait”

Back when I was sixteen I started by driving heavy duty farm trucks. These were usually gas powered, slow and had a 4 or 5 speed transmission with a two speed axle. Top speed loaded was generally 50 miles per hour.

Grain would blow off the truck but most people didn’t think much to take time tarping. The trip to the grain elevator wasn’t usually that far anyway. I really didn’t start dealing with a tarp until I drove a semi truck. I’m glad to inform that covering the commodity has improved tremendously over the years.

The size, of the truck, and hauling capacity grew as my experience and skill level improved. The miles to destinations, of delivery, started increasing. Instead of the local grain elevators being the unloading facilities, I hauled to river terminals, train depots, and processing plants. A major part of hauling became dedicated to hauling from the elevator instead of to it.

End dump trailers are a versatile asset to Ag support. Hopper bottom trailers are limited to only hauling grain and feed. I have hauled some different, not typical, commodities over the years. Coal is not fun to unload from a hopper, it actually can be work getting out of a dump trailer. I’ve hauled sand in a hopper, which is very heavy.

Anything that goes in a end dump will come out the tail, once the trailer gets tilted.

End dump unloading dry fertilizer into a conveyor

Great care must be exercised with a end dump. Stability must be insured when pushing the nose of a wagon to great height. There is a respected knowledge among drivers responsible for maneuvering dumps. Not all situations can be optiman perfect. “Theres dump drivers that have turned one over, and theres drivers that are going too!” I am still on the going to possibility after 15 to 20 years experience.

Most waterways in Illinois have a gravel quarry near by to them. This optimizes return hauls for dump trailers cutting empty miles from half loaded and half empty. Many times to this day I haul grain to the river and bring back lime, or rock. Dry fertilizer will come in on a river barge and that makes a very profitable return haul as well.

River terminals and train depots also distribute liquid nitrogen to fertilizer plants. Liquid tankers will be called upon for the spring planting season.

Ag support transportation has made some great labor saving advances. The drivers duties have become much easier, more efficient and most importantly safer. In part 2 of this article I will focus my observation mostly on driver duty improvements handling hopper bottom and end dump trailers.

Doug’s Dream, is Becoming Reality

I heard a great story, while having dinner with the Edwards family. Jim actually has shared many great tales of how Doug discovered his talent painting. Doug’s younger brother Jason must have been one of the first customers receiving Doug’s skilled handiwork. Jason had a new bicycle that wasn’t really a desirable color. A can of spray paint and the problem was solved. There were repercussions, but for the telling of this story the follow up isn’t necessary.

Doug’s talent has grown from his childhood. He has demonstrated his abilities with many beautiful tractors restored. His work hasn’t only been limited to antique tractors though.

Doug’s 1957 Dodge D-100. He restored this one for himself

Motorcycles, cars, and trucks have been challenges that he has taken on. Heavy Caterpillar equipment has also seen new beauty from Doug’s hand.

There have been three previous paint shop set ups before Doug finally got his newest building. His first two were in Waverly. For one reason or another the shops were closed, but our hero never gave up his desire. The H he painted for me was actually a small enough tractor he could take it on in his garage. It was a crowded work area. He made do and kept at his dream.

Joe Moeller, a friend and neighbor, came on the team working in the garage space.

Joe started out doing prep and sanding work for Doug. Joe is always willing to be right in the mix and valuable help. Doug has been teaching Joe how to master painting and his skill level has quickly improved. Currently Joe has taken on a restoration on his own for Doug. He is “shop foreman” now so Doug has given him the lead painting a Farmall 240. This makes having more than one project going easier. Freeing Doug’s productivity level to do more.

Theres no denying who the real boss is though. Sam oversees everything and keeps the operation running smoothly.

The shop can be a busy place. Since opening the new building, in November 2018, a Farmall Super H, Oliver 550 and 1800 plus a lawn & garden puller have been completed. There have been several other smaller projects and the waiting list has been quickly growing.

Doug’s staff has grown with the increased work. He has a electrical specialist and a prep worker to help out.

The building has been laid out in two separate work spaces. There is a area dedicated to painting. Both work zones have a overhead door leading outside and there is also a large pass through between the prep and painting zones.

It was designed for the Midwest weather. Projects can be moved without losing the warm controlled environment needed to work during winter. The paint area is properly ventilated and air circulation is safely controlled.

Edwards Vintage Tractor & Restoration is a full service company creating it’s own special “niche” in antique tractors. There is more to a good restore than bringing back the initial show room presence by painting. Many tractors have their own unique issues to overcome. For example, during the restoration of my H, Doug discovered there were two different size front wheels. This had to be corrected.

Doug strips a tractor down during the process. Generally this is a great time to replace worn parts and make conversions. Some people consider converting from 6 volt to 12 volt electric systems during the rebuild. New tires are also often considered. Whatever the work, the staff has experience and knowledge to preform the duties needed.

Doug has plans to expand his enterprise. I have no doubt with his dedication and support from his “people” the new business has a very bright future.

As the company grows, it will probably never get so big that a customer won’t be treated as a friend. The Edwards family are down to earth good people. Every team member is active in community events and they support several local service organizations and schools. They conduct business accordingly.

Thanksgiving Reflection

http://Thanksgivingreflections

I have discovered it very hard to be an active blogger with a career driving in the ag business industry. Lately I’ve been working harder as a novelist, during my writing time, preparing my “bestseller”

This fall was extremely hard anyway. On September 10th I had a minor accident and broke my right wrist. Life is hard enough without living it one handed.

I have to proclaim I’m thankful for tractors during this time of thanks. I’m sure many would not be all that surprised I say that. I have become known to be all about tractor. I come to realize there is more to why though. Here are two examples as to how tractors became more than iron tools and share life.

My collection is ever changing. One tractor I purchased didn’t actually stay though. I had a Case 830 for only three months. More importantly though, the seller and I have become very good friends. These past years of buying, selling, and trading have been fortunate that I can claim that in most every deal I do.

I didn’t own the tractor long, but Nathan Reinhart and I built a strong friendship bond well beyond that. Nate and I converse many early mornings as we travel for our work. Our topics can be very broad and complex. We have shared wisdom and solved many world crisis together. I kid him that he can just as easy turn his AM/FM on as call me. Our morning talk continues though and I’m hoping will for some time to come.

My life has become very solitary. I have a very hard time allowing anyone in my circle of trust now. This defense is harsh, but those that have become close are very important to me. Another family I share a strong friendship with, came about from restoring my 1947 Farmall H.

Doug Edwards had finished the H and allowed my first viewing of it on Christmas day two years ago. That appointment was special enough discovering my new toy just the same as when I did as a youngster.

I had gone to Franklin that late morning, for the appointment, fully intent not to intrude on Doug’s personal time for very long. Christmas is a time for family and friends, not a business transaction. I soon discovered that I would quickly become included in their circle. It was business, but it was between friends.

I met Jim during that time. The rest of the day and into that evening was shared talking. I had my first viewing of the Edward’s collection. I will always remember that very special day and be forever grateful.

Doug and I still work closely together, helping each other realize a life dream. Its strange how a artistic tractor restorer and a aspiring writer can support each other so well. We do though. I’m thankful for the Edwards family support and encouragement and will always be there for them.

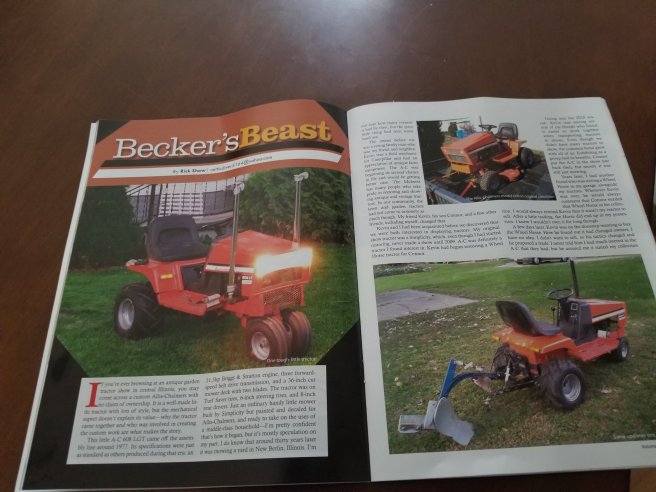

My first writing to be published in a magazine came about as a commission work for Jim. I recently was called on to write again and that article will soon be on the press.

So this is just two examples as to why I’m thankful for tractors. Its not necessarily the iron, its about the owners.

Happy Thanksgiving!

It’s All in a Name

I’m not one to make quick change. After a year of thought, consideration, and consulting with trusted friends I came to decide on the new name. I want to thank my friend James Hunt for the brilliant idea choice. Antique Iron Media closely resembles and shares the same initials as the Antique Iron Mafia that I founded on Facebook four years ago.

The name change is just one of several steps I will be taking to advance my writing further. Steps are being taken to make my musings more searchable on the Internet. Stay tuned for the bigger and better plans to come!

I also want to take the time to Thank those of you that support and follow my writing. Your continuing support means the world to me!

Then and Now, Spring Planting

Spring planting has definitely advanced from the past. Amazingly the implement’s basic design hasn’t really changed as much. The modern planter still employs gears and chain drive propelled off the wheels just the same as older planters. Plates are still used to help determine seed population. Modern planters have larger seed carry capacities and other advanced technology. The biggest and most obvious change would be size.

The first mechanical planters were, more than likely, powered by horse. The guidance system was probably dead reckoning. This method of guidance is still used some with other farm tools to this day. Not every farmer can afford GPS system. Star wars technology is becoming more common though.

Straighter rows were achieved with the advancement of simply a guide arm or marker on each end of the planter tool bar. The marker arm acted as a guide placement for the next pass. The farmer would center his tractor on the marked trench created by the arm thus determining the proper row spacing.

Row spacing has been changing throughout the years. When I was younger, the farmer I worked for planted a 36 inch row spacing. That was a common space and had been for some time. Row spacing was starting to narrow to 30 inch creating a better yield since the corn population increased because of more rows. The farmer I worked for changed to 30 inch spacing in soybeans. It wasn’t quite as simple to change to 30 inch corn rows. During harvest a corn header that was designed for 30 inch was needed. They had a 36 inch header. Headers are expensive. Small grain headers are different designs and can take any row spacing. Smaller grain can be grown closer together. Our farm employed a drill for soybeans with a row spacing of a mere seven inches Corn row spacing is common at 30 inches now. Some farmers are are growing crops closer together though.

My grandfather told me, years ago, about planters using wire strung across the field to determine seed placement. I was at a show recently discussing the “good ole days” and learned more about this technique. It’s no wonder the farmer of the day didn’t get obese. There was plenty of exercise getting on and off the tractor to move the wire. Interestingly, the seed was spaced within the row far enough apart that they culivated with the row and across it.

The planting machine has been evolving. It is increasing in size and row capacity. Once it was a small one or two row, doubling in size to four. Doubling again, and again, and maybe again. I remember tending an 8 row planter and that was a good size with a lot of work involved to plant. The grain company / farm I’m employed by now utilize two planters, a 16 row, and 24. Surprisingly the work tending the large planters has be come easier. It’s hard to believe, but there are bigger planters than that!

New technology came about to increase the planter seed carring capacity. A large seed tank and pushing the seeds to the row via air. Many companies picked up on this and the farmer began spending more time planting and less time actually filling the planter to plant.

Preperation tillage has changed in my time. The soil isn’t worked as much to a point of not at all. No till and modern chemistry has eliminated the need for mechanical weed removal. Some farm tools, like row culivators, are now just history. The mullboard plow isnt as commonly used now because of soil erosion. It scares my old school type thinking of our agricultural dependancy on chemicals now.

My job, tending the planter, has become easier. Seed came in sacks and each row box had to be frequently filled. Back then tending the planter built muscle, just like handling hay bales. Soybeans where made easier with the use of a auger mounted under the door of a gravity flow wagon. The farm I worked used a John Deere A to move the bulk seed wagon and operate the hydraulic driven auger. Loading the planter boxes and the tank on a drill was made easy.

Now the seed gets delivered, to planters, from large seed boxes. There are special designed trailers that the boxes can be placed and unload into a auger conveyor. It’s now just a simple matter of starting a small engine, open a slide gate and the seed is loaded into the large planter tank. Little fuss and a lot less muscle! The seed corn sack hasn’t become a memory yet though. They still are around. The planter tender needs to know how to operate a fork lift. Also they need the skill to move a top heavy trailer swiftly but carefully to the fields from the storage warehouse. There is other means of tending the seed, the box method was the system, the grain farm/ elevator I work for employs.

It’s now just a simple matter of starting a small engine, open a slide gate and the seed is loaded into the large planter tank. Little fuss and a lot less muscle! The seed corn sack hasn’t become a memory yet though. They still are around. The planter tender needs to know how to operate a fork lift. Also they need the skill to move a top heavy trailer swiftly but carefully to the fields from the storage warehouse. There is other means of tending the seed, the box method was the system, the grain farm/ elevator I work for employs.

GPS technology has made tillage more accurate and efficient. The planter marker is now becoming obsolete. Most planters still have them, but they don’t see much use now.

It was good to be involved with the spring planting again this year. This is my take on then and now….